Project layout

Labels:

automation,

control,

daq,

detection,

gamma,

inspection,

Lab View,

measurement,

motor,

radiation,

relay,

sca

Award Winning Project

Alexandria University organizes a Project Day for its engineers to show their work, a large audience witnesses this day every year. College professors, working engineers, sponsors and students who are seeking someone to look up to.

We won the first place on behalf of our department and a financial prize from Sumed Pipeline.

We won the first place on behalf of our department and a financial prize from Sumed Pipeline.

Labels:

award,

certificate,

inspection,

nuclear,

pipeline,

project day,

radiation engineering,

rpi,

sumed,

winners

Conclusion

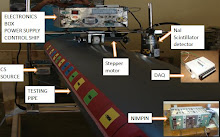

The Robotic Pipeline Inspection system by gamma radiation was set to scan pipelines over long distances for wall thickness changes, to identify those defects and locate them.

The system consists of:

- A detection system; detector, gamma emitting sources & NIM BIN.

- A/D converter or a DAQ system; USB DAQ card, LabView software for instrumentation, investigation, automation and control.

- Robot; powered by a stepper motor and its control circuit.

The experiment was done using a test pipe having different thicknesses marked along its length. Cesium sources emit gamma rays that are absorbed within the walls of the pipe, the question is how much got absorbed?? That indicates the damage extent.

The RPI system is controlled by a computer software we designed for this special purpose, to move the system and analyze the detector's output.

The detector is powered by a HV supply in the NIM BIN, the output signal is really weak and needs an amplifier, later on it's subjected to a SCA to cut the non required energies.

The Signal is transmitted to the DAQ card counter ports to be analyzed and to perform the required calculations and obtain an understandable form of results indicating the variation in the pipe wall thickness along its length.

The stepper motor receives its signal through the relay controller circuit, which is composed of a ULN2003 IC and 4 relays (switches). The software sends a digital signal to the relay board controlling those switches and subsequently rotating the motor shaft, gears transmitting motion to the frontwheel, transfered by a couple of pulleys and a belt to the rear wheel, hence moving the system.

RPI is an intelligent system, that achieves the goal it was designed for, having the flexibility to cover various pipe diameters (20-60 cm), a friendly user interface and a simple operation mode. Thus it has its limitations also; it cannot overcome some barriers, cannot move underground, and has a fair uncertainty in measurement which is due to our lab limitations.

Further work can be done to improve the overall performance of the system, improvements we are working on.

Labels:

conclusion,

daq,

detection,

gamma,

graduation project,

inspection,

labview,

rpi

About Us

We are the students of the fourth year -semester June 2008- in the Nuclear and Radiation Engineering Department, Faculty of Engineering, Alexandria University, Egypt.

Project General Supervisor:

Prof. Dr. Mohamed Y. Khalil

Nuclear Engineering Department

Prof. Dr. Mohamed Y. Khalil

Nuclear Engineering Department

Project Crew: (in an alphabetical order)

Amr Mohamed

Asmaa Mohamed

Hala Abd-elkerim

Hossam ElDin Mass'oud

Mohamed Said

Rasha Rashad

Labels:

engineering,

graduation project,

inspection,

nuclear,

pipe,

radiation

Subscribe to:

Posts (Atom)